vickers hardness test sample preparation|hv full form in hardness : bulk When using the Vickers hardness testing method, it is usually necessary to prepare the surface of the specimen to be tested, as the specimen surface quality requirements are significantly stricter than those for the Rockwell method, in . WEBOs irmãos goianos Matheus e Kauan, naturais de Itapuranga/GO, já nasceram unidos pelo gosto musical e escolheram desde cedo a música como profissão. Com um repertório repleto de sucessos .

{plog:ftitle_list}

15 de jun. de 2023 · Ribeirão Pires 27° C . A Jadlog notificou extrajudicialmente a empresa Facebook Brasil, representante da Meta no país, sobre as páginas falsas. Contudo as páginas permanecem no ar.

When using the Vickers hardness testing method, it is usually necessary to prepare the surface of the specimen to be tested, as the specimen surface quality requirements are significantly stricter than those for the Rockwell method, in .1. Place your sample on the stage. 2. Click and drag the mouse to move the sample into position. 3. Scroll to focus. 4. Select the test method and load. 5. Choose an objective and job name. 6. Use the overview camera to position .The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad .

Sample Preparation: The material sample should be smooth & flat. Surface preparation might involve polishing to ensure accurate measurement. Setting the Testing Machine: The . Sample Preparation: The material to be tested must be prepared carefully. It should be flat and free from any surface irregularities that could affect the results. Indentation: The sample is placed on a rigid surface, and the .

Additionally, the sample preparation will need to make the specimen’s surface smooth to permit a regular indentation shape and good measurement, and to ensure the sample can be held perpendicular to the indenter.Find an overview of the Vickers methods and their applications depending on the load range as well as an explanation how to choose the right test load.

What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs.The Wilson VH1150 Macro Vickers Hardness Tester is the ultimate macro-Vickers hardness tester. Boasting a unique load range of 300gf – 50kgf, enjoy its user-friendly operation with automatic load selection and a seamlessly . Vickers HV Macro hardness test: - ground Micro hardness test: - polished - electropolished Knoop HK Micro hardness test: - highly polished 3. Description of principles For hardness indentation tests, where the size of the indent is determined opti-cally, as for Vickers, Brinell and Knoop, the hardness is defined as the applied

Explore the Vickers Hardness Test, its methodology, and applications in material science. Detailed guide available at Infinita Lab. . Sample Preparation: The material sample should be smooth & flat. Surface preparation might involve polishing to ensure accurate measurement. The Vickers hardness test, an offshoot of the venerable Brinell test, has been used since the early 1920s. Although the concept of using one test method to cover a wide range of materials hasn’t changed much in the last 90 years, upgrades to the equipment used to perform the test have expanded its use and accuracy. The Vickers hardness number is the load (test .Wilson VH3100 and VH3300 All-in-One Ordering Part Number Description Request a Quote W3100 Fully-Automatic Vickers tester with macro & micro ranges, Load range 0,05 - 10kgf, High Performance Workstation with DiaMet Enterprise Control software, & 10x and 50x long working distance measurement objectives and overview camera

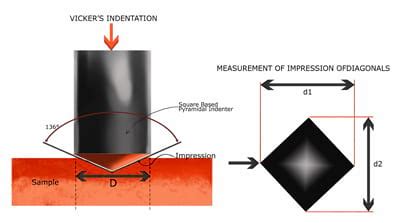

The indenter employed in the Vickers test is a square-based pyramid whose opposite sides meet at the apex at an angle of 136º. The diamond is pressed into the surface of the material at loads ranging up to approximately 120 kilograms-force, and the size of the impression (usually no more than 0.5 mm) is measured with the aid of a calibrated microscope. Among the many methods for measuring hardness, the Vickers Hardness Test stands out for its precision and versatility. . Conducting the Vickers Hardness Test. Sample Preparation: The material to be tested must be prepared carefully. It should be flat and free from any surface irregularities that could affect the results.

Wilson® VH3100 Vickers & Knoop Hardness Testers. The VH3100 Vickers and Knoop hardness test system features a 3-position virtual turret with one Vickers indenter and two measurement objectives, an automated X/Y sample stage (110 mm x 140 mm travel range), a bright field overview camera for sample navigation and scanning and a powerful image analysis.

The Vickers hardness test has two distinct force ranges, “Microindentation Vickers” (10 – 1000g) and “Macroindentation Vickers” (1 – 100kg), to cover all testing requirements. The indenter is the same for both ranges; therefore Vickers hardness values are continuous over the total range of hardness for met- als (typically HV100 .The Vickers hardness test uses a Vickers indenter, which is shaped like a squat pyramid and is typically pressed into the surface of the material for 10 seconds. The amount of force used is of a pre-determined amount and varies depending on the materials being tested. . That said, careful sample preparation is necessary to ensure that the .A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.

vickers microhardness test procedure

The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. This Vickers hardness test is usually easier to use compared to other hardness tests. . Additionally, sample preparation is crucial to achieving a .

The Vickers Hardness number (HV) is then calculated by dividing the applied load (in kgf) by the surface area of the indentation (in square millimeters). The result is a unitless number, making it easy to compare the hardness of different materials. Conducting the Vickers Hardness Test. Sample Preparation: The material to be tested must be .The Vickers test often has strict specimen requirements due to the high sensitivity of the optical reading instrument and the need to get an accurate result. This article provides what you need to know for adequate preparation of your specimen for an accurate Vickers hardness test.The Wilson VH3300 offers an advanced, fully automated hardness tester for fulfilling both Vickers and Knoop hardness testing requirements. Designed for all users from novice to expert, it utilizes quick and straightforward operation without compromising the flexibility required for advanced applications.

The Vickers Hardness Test involves pressing a pyramid-shaped indenter with a precisely known load into the material's surface. The indenter typically has an angle of 136 degrees between opposite faces. . Sample .

Learn all you need to know about materialographic preparation of different materials, metals and alloys – from sample preparation through to structure microscopy analysis – with expertise and insight from Struers, the world’s .By applying our expertise in sample preparation and high-quality production, in-house processing delivers test blocks with the highest quality surface finish. Trusted All Wilson test blocks are calibrated in the Wilson Hardness Calibration Laboratory in Binghamton, NY. The Micro Vickers hardness test uses a traditional Vickers type indenter, but at a microscopic scale. This indenter is a square-pyramidal shape and is typically pressed into the surface of the material for 10-12 seconds. . Sample Preparation . Sample Cutting - Given that specimen sizes for microhardness testing and the size of the tester .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

Hardness testing is a fundamental aspect of material characterization, providing valuable insights into a material's mechanical properties and suitability for various applications. Among the different hardness testing methods available, the Vickers hardness test stands out for its versatility, precision, and wide range Hardness evaluation is a critical aspect of material testing, providing insights into a material's resistance to deformation and wear. Among the various methods employed for hardness testing, the Vickers test stands out for its precision and versatility.. The Vickers test, developed by George E. Sandland and Robert L. Smith in 1921, utilizes a pyramidal diamond .

Learn all you need to know about materialographic preparation of different materials, metals and alloys – from sample preparation through to structure microscopy analysis – with expertise and insight from Struers, the world’s leading materialographic and metallographic experts. . How to use the Vickers hardness test for a wide range of .

Vickers number 1 2 Average 1 0 0 0 312. 2 0 0 0 315. 3 0 0 0 317. 4 0 0 0 292. ANALYSIS Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is indicated by a higher HV. Vickers hardness values are a useful tool for comparing the hardness of various materials . The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to hard ceramics, and is especially valuable for micro hardness testing requiring small, accurate measurements. . Sample preparation: Ensure that the sample surface is properly prepared, free of contaminants, and has a smooth .

vickers hardness test procedure

The Knoop hardness test is similar to the Vickers test but uses a rhombic-based diamond indenter instead of a pyr-amid. It is commonly used for measuring the hardness of thin . Rockell is a depth difference method and measures a distance by applying different loads to a sample. Regardless of the indenter and test load, the testing cycle .

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals. ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials.

Selecione o número de jogadores. Nesta versão de Ludo Online você pode jogar com 2 ou 4 pessoas; Escolha um avatar e defina um nome para ele; Comece a partida. A cada rodada, um dos jogadores joga o dado e movimenta os peões de acordo com o número sorteado; Vence o jogo quem conseguir levar primeiro seus 4 peões para o centro do .

vickers hardness test sample preparation|hv full form in hardness